Project Management for First-to-Demo Prototypes and Low-Volume PCB Assemblies

NPI Services: Bridging R&D to Mass Production

NPI (New Product Introduction) services are critical for transitioning new products from R&D to successful mass production and market launch, providing essential support for pilot phases and validation.

1. Your Strong Support for Pilot Phase

As the product's critical validation stage, our NPI services deliver comprehensive functional, performance, and reliability testing (including extreme conditions). We precisely pinpoint design issues, laying a solid foundation for optimization and mass production.

2. Reliable Assurance for R&D Validation

Our NPI services rigorously validate product stability, compatibility, and durability by simulating real-world usage scenarios. This ensures reliable, long-lasting performance in application, building customer trust.

3. Core Value

4. Choose Our NPI Services

In the semiconductor and electronics manufacturing sectors, we leverage deep expertise and technical strength to provide professional pilot and validation support. Partner with us to build more reliable, outstanding products and succeed in the market!

1943 stands as your premier destination for PCB assembly services in China, providing an all-encompassing solution that caters to your project’s scale and complexity. Whether you’re in the early stages of prototyping or preparing for mid-scale production, our services are designed to meet your diverse needs seamlessly.

Our surface mount technology (SMT) assembly service boasts precision and efficiency, ensuring the accurate placement of components ranging from standard resistors to sophisticated integrated circuits. We excel in ball grid array (BGA) assembly, showcasing our proficiency in handling complex components with finesse, ultimately contributing to optimal performance.

Through-hole assembly is seamlessly integrated into our comprehensive suite of services, accommodating a variety of component types and ensuring robust connections. Our expertise extends to mixed assembly, where we adeptly combine SMT and through-hole technologies to meet the unique requirements of your design.

In addition to these capabilities, we specialize in rigid-flex printed circuit board assembly, providing a flexible and durable solution for applications demanding intricate and dynamic designs.

7 automatic SMT production lines

Production capacity: 15.32 million soldering spot per day

Proportion of capacitance and resistance loss: 0.3%

Mounting general FR-4 PCB, FPC and FPCB

Minimum package : 0201chip / 0.35 pitch BGA

Minimum mounting accuracy :± 0.04mm

IC mounting accuracy: ± 0.03mm

PCB size: L50 * W50mm - L510 * w460mm

PCB thickness: 0.3mm-4.5mm

With the professional engineer and purchasing team, we serve our customers BOM improvement, components collection and selection, and solutions of the full BOM for thousands of customers every year.

We are devoted to provide a strong guarantee for customer R&D and the production of small and medium batches of products.

We only purchase from original factory and formal agents, carefully select procurement channels for our customers over many years, have an intact supplier inspection system. Insist on original genuine components to ensure the quality.

Customers can purchase according to the required quantity, not need to purchase the whole package, and truly achieve zero inventory of materials.

The warehouse covers an area of 1000 square meters,stock common tape materials such as resistance capacitance, inductance, magnetic beads, crystal oscillator, etc.

"First-in, first-out" material control mechanism, warehouse management: constant temperature and humidity, anti-static control. Strict and standardized 100% IQC incoming inspection to resist receiving bad materials.

The management personnel of the company have more than 10 years of experience in components procurement and management, professional component certification engineer and BOM engineer.

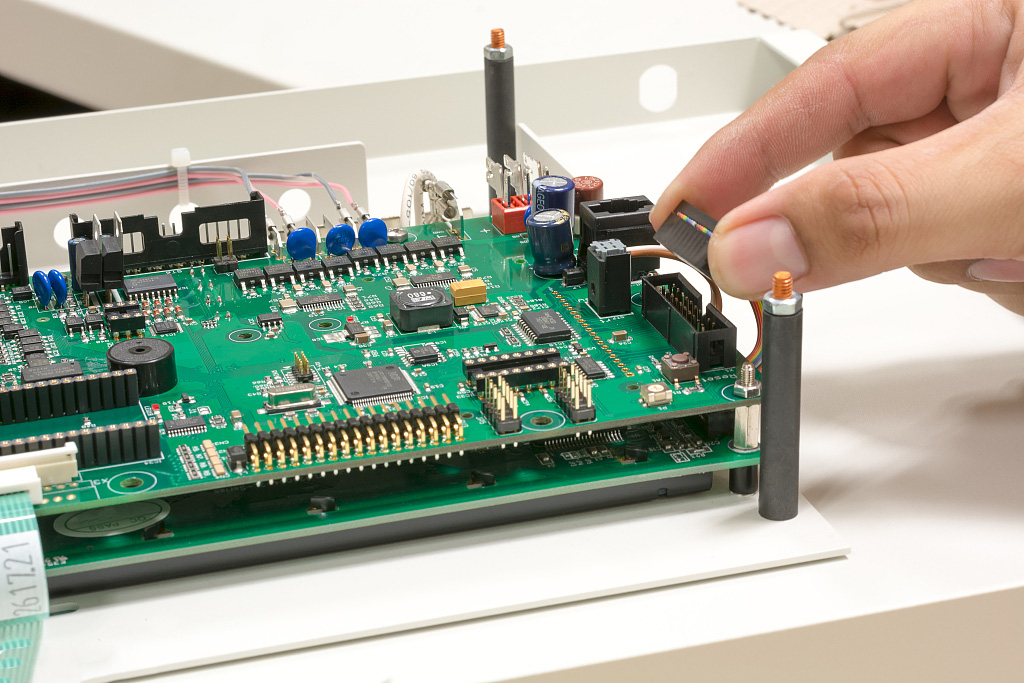

Adheres to the one-stop service concept, 1943 provides our customers with services such as device programming, finished product assembly, functional testing, and special processes. The company is equipped with professional personnel and flexible production assembly lines, which can be competent for small and medium batch finished product assembly tasks.

There are two 10-meter assembly lines, 24 standard assembly stations, many years of finished product assembly experience, familiar with various product assembly processes and standards, products covering communication and IoT, transportation, industrial control, medical equipment and other fields. From PCB’s to finished product, it can be delivered directly at one time without changing factories!

Existing 20 test stations. Configure test computer, oscilloscope, desktop multimeter, DC adjustable power supply and so on. Test each function of the product according to customer requirements and provide test reports. We can provide services such as electrical measurement and aging according to customer needs to improve product reliability. For each process, 1943 formulated intact operation instructions, customized targeted inspection standards according to products in different industries, and improved the straight through rate of products from all links.

General product packaging consists of anti-static bags, bubble bags, spacer strips and ultra thick cartons. Special products shall be specially packaged and drop tested to avoid product performance damage caused by external forces during transportation. At the same time, we can also provide customized packaging services.

Enterprise strength

Enterprise strength

Shenzhen 1943 Technology Co., Ltd., established in 2015, is a high-tech enterprise focusing on

industrial PCBs manufacturing, providing customers with one-stop solutions such as PCB design, SMT

patch, centralized device purchase, test assembly, failure analysis and so on.

The company has 5000 ㎡ independent plant, 7 high-end SMT production lines and more than 120

production personnel.

Raw materials, technology, quality control, delivery and service

Fast and reliable PCBA service provider

The enterprise has passed ISO9001:2015 and ISO:13485 international standard quality management system and ipc-a-610 level II and III certification, covering the whole process of product R & D, raw material management, standardized production, quality inspection and after-sales service.

The production line is equipped with high-end automatic production equipment and full-automatic optical detection instruments, whole process quality control, high precision and high yield. Carry out quality inspection and control in each process to avoid the outflow of defective products.

Products

Products1943 provides customers with high-precision SMT patch processing services, equipped with seven high-speed SMT patch production lines, and has long provided PCBA processing and manufacturing services to many customers at home and abroad.

Our service cases mainly include industrial control, medical electronics, communication Internet of Things, security equipment, and instrumentation industries, and the service content covers the entire PCBA processing and manufacturing process.

Including [PCB board making, component procurement, SMT patch processing, DIP plug-in, test assembly, three-proof paint coating, coding, marking] and other processes.

Through our professional services, products can obtain real production supply and stable and reliable quality dual guarantees.

Point:626

Types of components:107

PCB size: 176*174mm

Soldering process:Reflow soldering for double side+ Wave soldering.

Full processes: SMD processing + cleaning + anti-static packaging

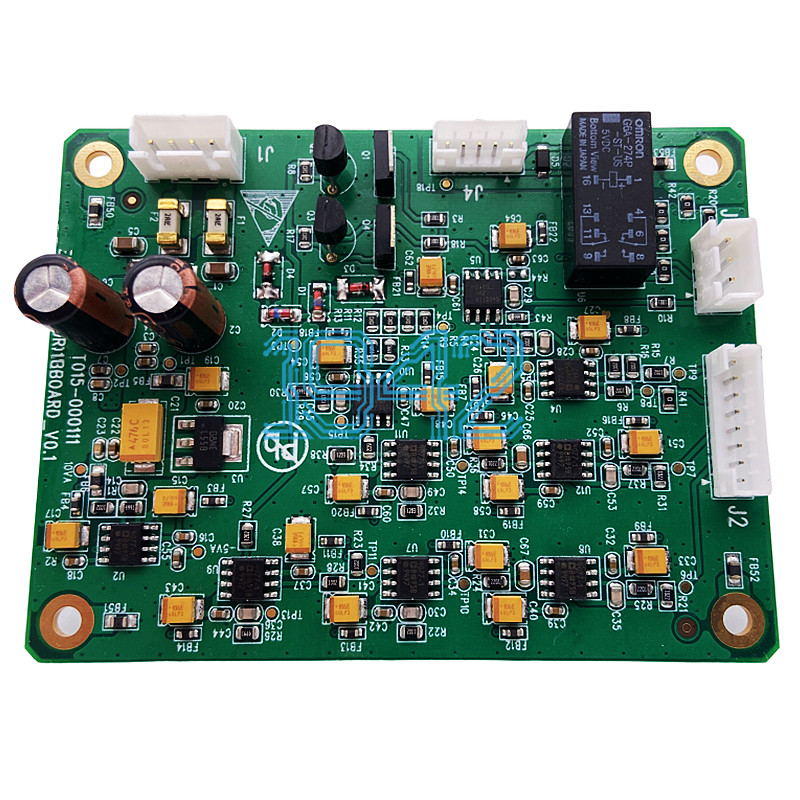

Point:149

Types of components:82

PCB size: 144*137mm

Soldering process:Reflow soldering for double side + Wave soldering.

Full processes: PCB producing + components procurement + assembly

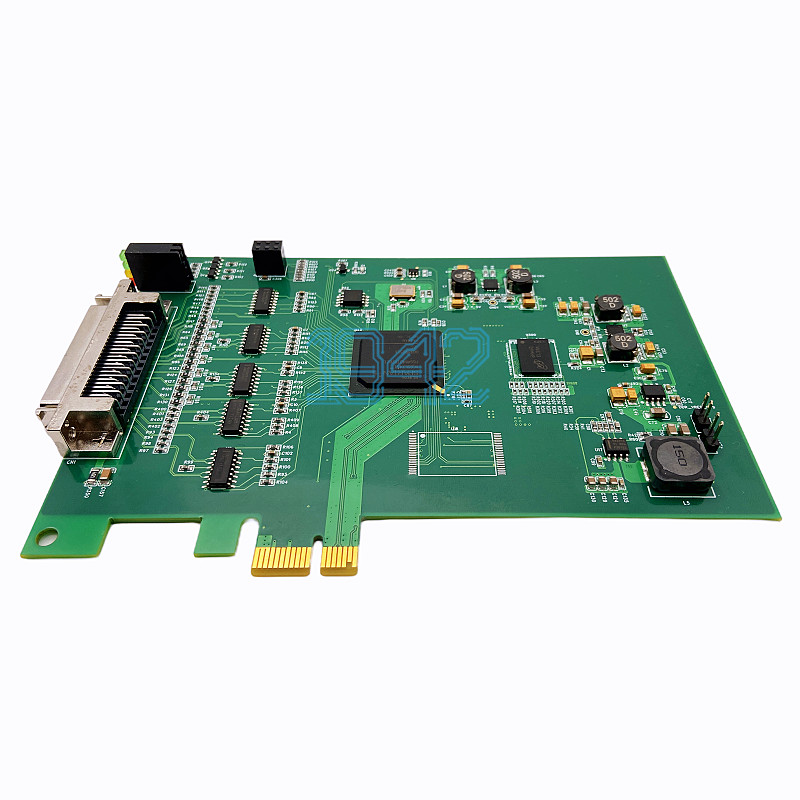

Point:124

Types of components:56

PCB size: 123*102mm

Soldering process:Reflow soldering + wave soldering

Full processes: PCB producing + components procurement + assembly

Point:146

Types of components:62

PCB size: 167*124mm

Soldering process:Reflow soldering for double side + Wave soldering.

Full processes: PCB producing + components procurement + assembly

News

News

Let the products quickly and stably realize marketization and become the global electronic intelligence innovation enabler