Raw materials, technology, quality control, delivery and service

Our company gives full play to its competitive advantages in component procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at domestic and abroad around the world to ensure the quality and stable supply of raw materials. It can help customers save the cost of components and reduce the risk of customer procurement to the greatest extent.

1. Full BOM component supply, lower component procurement cost.

2. Strict and standardized 100% IQC incoming material inspection, and resist receiving defective materials.

3. Purchasing from original factory and formal agents, carefully select procurement channels for our customers.

4.Customers can purchase according to the required quantity, not need to purchase the whole package, and truly achieve zero inventory of materials.

5. Non-standard devices or components in BOM shall be recognized and sealed according to the specifications.

6. Select materials with high reliability and stability, meet the industrial PCBs standard, provide material test report, and meet the ROHS environmental protection requirements.

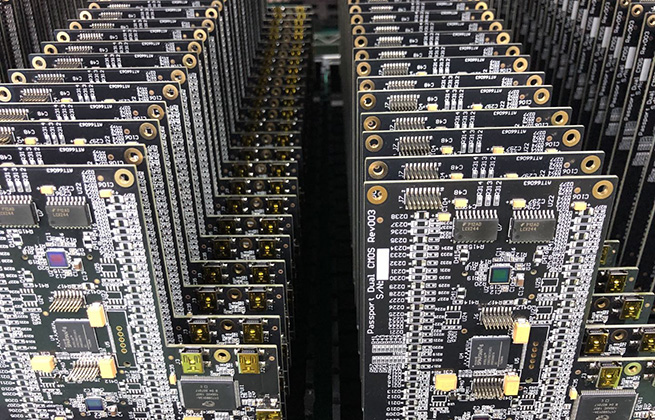

A team of more than 12 senior engineers in the electronics industry, with 13 years of industrial PCBs manufacturing experience, has completed product introduction and process improvement for more than 6000 times, providing customers with accurate PCBs full process solutions.

1. BOM review: special inspection software embedded tools review you BOM, optimize components' descriptions, Part numbers, quantity, tag numbers, packaging, brand and other parameters.

2. PCB Design: a team with 17 years of PCB design experience in communication, industrial control, energy and other fields; Familiar with circuit, device, structure, EMC, safety regulations, high-speed signal, reliability.

3. DFM analysis: PCB professional engineers are good at test of electronic products, PCB / PCBs board technics design, inter board interconnection design and environmental adaptability design.

4. Test and function analysis: customize the test fixture according to the schematic test requirements, and analyze the function of the tested defective products.

5. One set of process parameter files for one product: improve and optimize the SOP and process parameters according to PCBs and production characteristics, and form a standardized process parameter file.

The whole processes from invoice signing , placing order, data review and conversion, SOP guidance, manufacturing and installation, production management are controllable and traceable , 100% AOI detection, and the product qualification rate is as high as 99.8%. Continuous improvement to deliver "0" defects products.

1. Extrapolate the project process with Gantt chart and follow up NPI trial production.

2. Controlled documents shall be prepared for each order; Strictly manage the conversion and review of engineering data.

3. 7 high-end production lines are uniformly equipped with SPI (3D solder paste tester) to ensure that SMT process solder paste coating meets industrial standards.

4. Select brand solder paste to ensure the reliability of SMT soldering.

5. The responsibilities of IPC, IPQC, QA and QC quality control posts are clear, and the IPC electronic assembly acceptance standards are strictly implemented.

6. With regard to PCBs testing, we have professional engineers who use various test racks to test 100% of the products, including circuit, noise, amplitude, signal, temperature, humidity, drop or implement the customer's detailed test scheme.

7. Pay attention to customer feedback after delivery and make QCC improvement plan around the feedback data.

Let the products quickly and stably realize marketization and become the global electronic intelligence innovation enabler