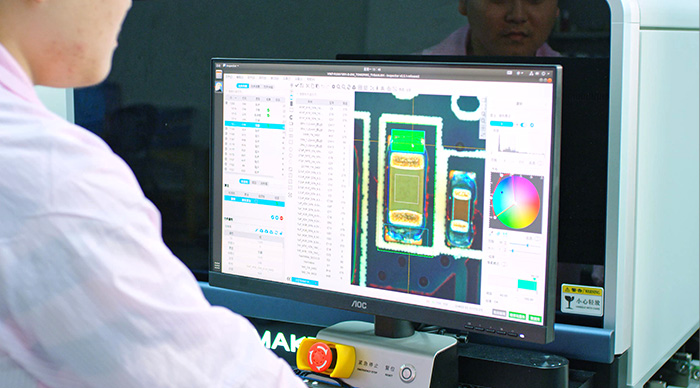

Our factory is equipped with 7 high-end automatic production lines. Brand new imported equipment and automatic optical testing equipment,such as AOI / SPI / X-ray, etc., which are more flexible and flexible to deal with small and medium-sized batch production. Especially good at high-precision, high mixing and high complexity production. Our PCBA capacity includes but is not limited to the following data we show here, because we constantly update our manufacturing process and production equipment with the times and customer's needs, and continuously develop and mine technologies that can bring value to customers, so as to maintain our front-end in the field of electronic manufacturing.

5000㎡ Workshop

Professional process engineer equipment engineer layout engineer procurement engineer and SMT DIP QC team with more than 10 years of industry experience

7 automatic SMT production lines

Production capacity: 15.32 million soldering spot per day

Proportion of capacitance and resistance loss: 0.3%

PCB types: general FR-4 PCB FPC and FPCB

Minimum package : 0201chip / 0.35 pitch BGA

Minimum mounting accuracy :± 0.04mm

IC mounting accuracy: ± 0.03mm

PCB size: L50 * W50mm - L510 * w460mm

PCB thickness: 0.3mm-4.5mm

2 wave soldering production line create 500000 dots/day. 2 manual soldering production lines create 30000 dots/day

20 test stations testing more than 3000pcs/sets per day.

2 end-products assembly lines with 24 stations more than 3000 units (sets) can be assembled per day.

Inspection standard: IPC-610H CLASS 2

IQC: Incoming check

IPQC: In process quality control

Visual QC: common quality check

SPI: check solder paste printing quality online

AOI: Check the defects of the SMT soldering online

8 hours for expedited sample order

15 days for PCB+ components purchasing+ SMT

Let the products quickly and stably realize marketization and become the global electronic intelligence innovation enabler