With the rapid development of electronic technology, surface mounting technology for electronic products production has matured in China. As electronic products become more and more precise and small, it means that the circuit of PCB will become narrower and narrower, and the electrostatic discharge capacity will become worse and worse. As a result, electronic components have higher and higher requirements for electrostatic protection in mounting production, which undoubtedly brings more difficulties and challenges to PCBs production. Therefore, our engineers discussed with you the hazards of static electricity and how to release static electricity generated in SMT process.

1、 Causes of static electricity in PCBs processing

1) The manufacturing process of electronic products starts from the surface mounting of components to the assembly of finished products. During this period, production equipment, processing tools, operating environment, packaging materials, etc. may be in contact with electronic devices. Contact separation, friction and induction between components and other objects will generate static electricity.

2) Most of the electronic components processed by SMT are semiconductor materials. Although the conductivity of PCBs is mostly similar to that of insulators before the finished products are put into use, there are many links from components to finished product assembly, and static electricity may be generated in each link. However, some electrical performance tests and function tests need to be powered on. Therefore, in these cases, if the semiconductor devices carry static electricity, It is likely to affect the performance of the finished product.

3) Although the production automation of modern electronic products is getting higher and higher, the whole manufacturing process is inseparable from the operation of personnel. Compared with the processing equipment, the range of operators' contact with electronic components is wider and more complex, and the static electricity generated by human body is much more complex than the equipment and environment.

2、 Harm of static electricity in PCBs production

1) When the electronic components of PCBs are installed through SMT process, even if the PCBs are not powered on, the components that have been welded may be damaged due to the existence of static electricity. It is well known that if the voltage between two or more pins of a component exceeds the dielectric breakdown strength of the component, the component will be damaged.

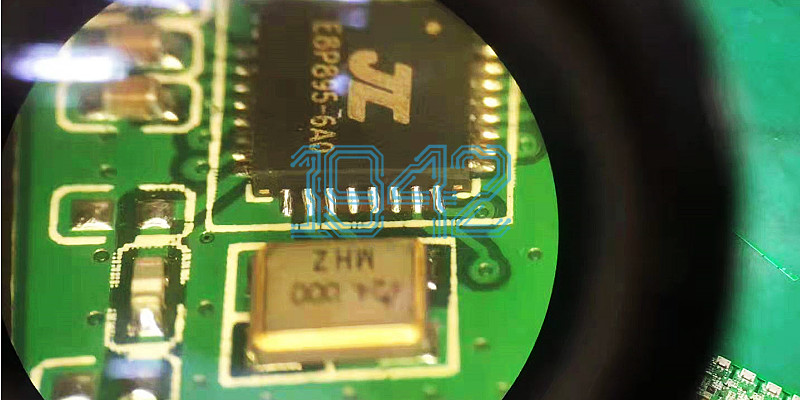

2)The instantaneous pulse energy of static electricity can make local PCBs or components heat up, so there may be the possibility of direct breakdown of components and IC. Even if the voltage is lower than the dielectric breakdown voltage, it may cause PCBs or component failure. After the electronic components themselves or the main chip are affected by static electricity, functional damage may not occur immediately. These potentially damaged components are usually found during use. Therefore, static electricity will affect the service life of PCBs.

3、 How to release static electricity in PCBs production

1) During SMT production, SMT operators are required to wear grounding electrostatic bracelets. Especially in the process of long-term contact with PCBs, the quality control personnel shall conduct electrostatic Bracelet test at least every 4 hours.

2) When manually soldeing the components of PCBs, the anti-static low-voltage constant temperature soldering iron shall be used as far as possible, and good contact with the electrostatic wire shall be maintained.

3) During the assembly of PCBs finished products, low-voltage DC electric screwdriver with grounding wire shall be used as far as possible.

4) Ensure that the production line equipment, workbench, shelf, electrostatic skin, etc. are in contact with the electrostatic line.

5) PCBs factories should make a separate wiring layout for the electrostatic wires instead of mixing the grounding wires and the electrostatic wires. This is completely incorrect. The electrostatic wire needs to be separately connected with the ground, and the ground wire is the grounding layout of zero fire wire. Do not confuse it.

As a kind of electric energy generated by friction induction, static electricity will bring serious harm to SMT processing and manufacturing industry, especially to SSD devices on integrated circuit boards. Therefore, during the production and manufacturing of PCBs, the enterprise should establish a complete set of electrostatic protection measures and management system, so as to effectively eliminate the generation and adverse effects of static electricity in the whole production process and ensure the quality of SMT processed products.

——By R&D department\ Shenzhen 1942 Technology Co.,LTD

#Shenzhen SMT plant #1942 SMT factory #PCBA# PCBs#PCB technology

2024-06-03

2024-06-03