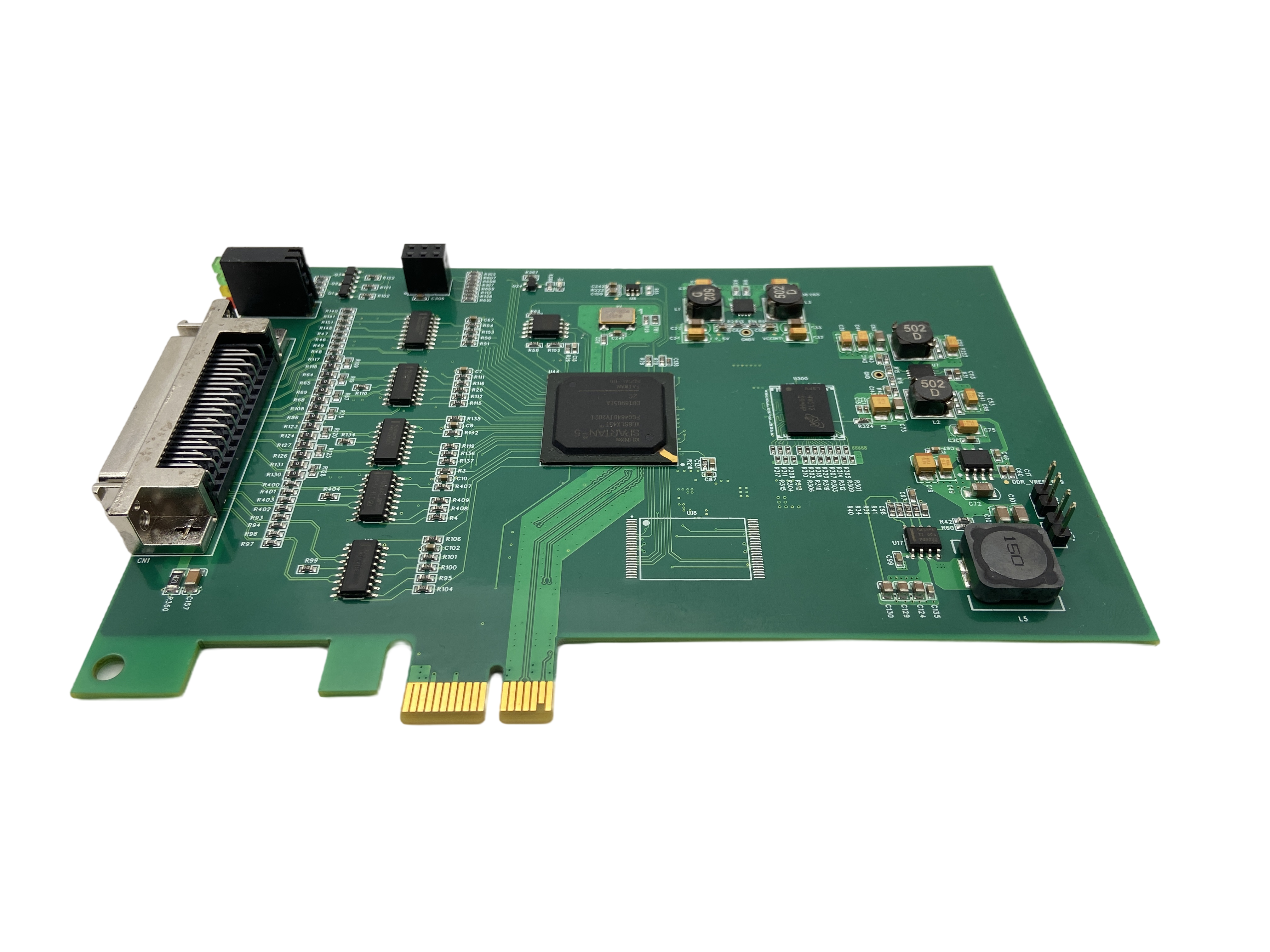

Point:146

Components type:62

PCB size: 167*124mm

Minimum package size of resistance capacitance sensing: 0402

Minimum device pin spacing:0.65

Welding mode:Reflow soldering for double side+ Wave soldering.

Manufacturing process: PCB producing+components procurement+assembly

Shenzhen 1942 Technology Co., LTD is a professional PCBs manufacturer, 7 SMT production lines ,5000㎡ factory

Main bussiness : PCB design , SMT, DIP, compnents soucing, function test , PCBA coating, PCBA failure analysis.

PCBs applications:

medial equipment PCB& PCBA

industrial control PCB$PCBA

IOT ( internet of things ) PCB &PCBA

drones PCB & PCBA

Video equipment PCB &PCBA

…………

The total number of front and back surface mount components is 146

The amount types are 62

The outer diameter of PCB is 167*124mm

The minimum package size of surface mounted components is 0402

The minimum pin spacing of surface mount components is 0.65mm

Components are soldered by double-sided reflow soldering machine & wave soldering oven

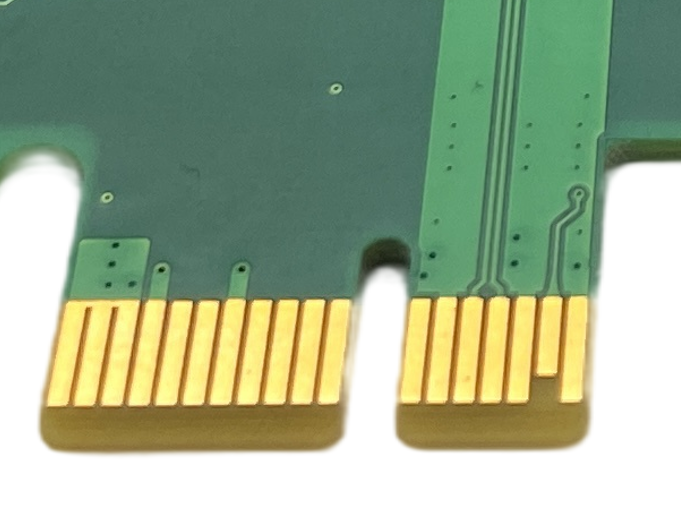

Gold Finger

There is a gold finger on this motion control card. If there is a defect in the production process of PCB, it is very likely to cause the gold finger to change color or black spots. Therefore, when we produce PCB, we adopt the electroplating process, and strengthen the cleaning treatment of the process after the gold coating and the 7S management in the PCB assembly process.

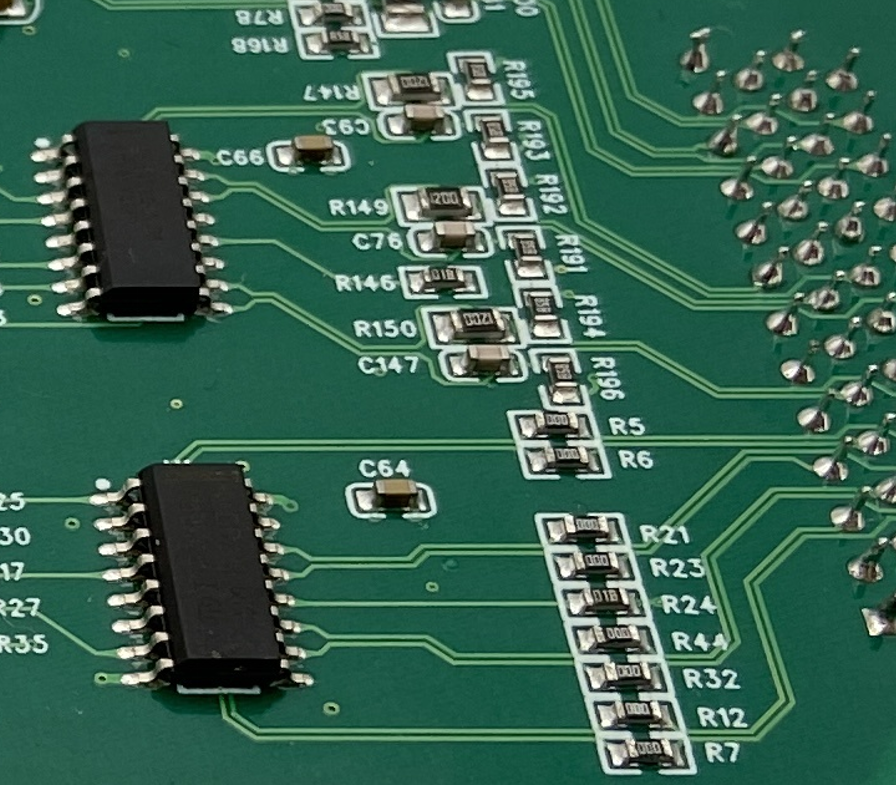

Soldering detail

Shenzhen 1942 Technology Co., Ltd. integrates the industry's senior expert consultants and the technical team with more than 13 years of industry experience to create a rapid response service system and stable and reliable technical support, and establish lean, reliable and convenient product delivery services in the field of electronic manufacturing; We can provide customers with PCB design, SMT , centralized device purchase, test assembly and failure analysis, and achieve one-stop delivery and supply services from PCB Design & board making to finished product assembly.