Point:384

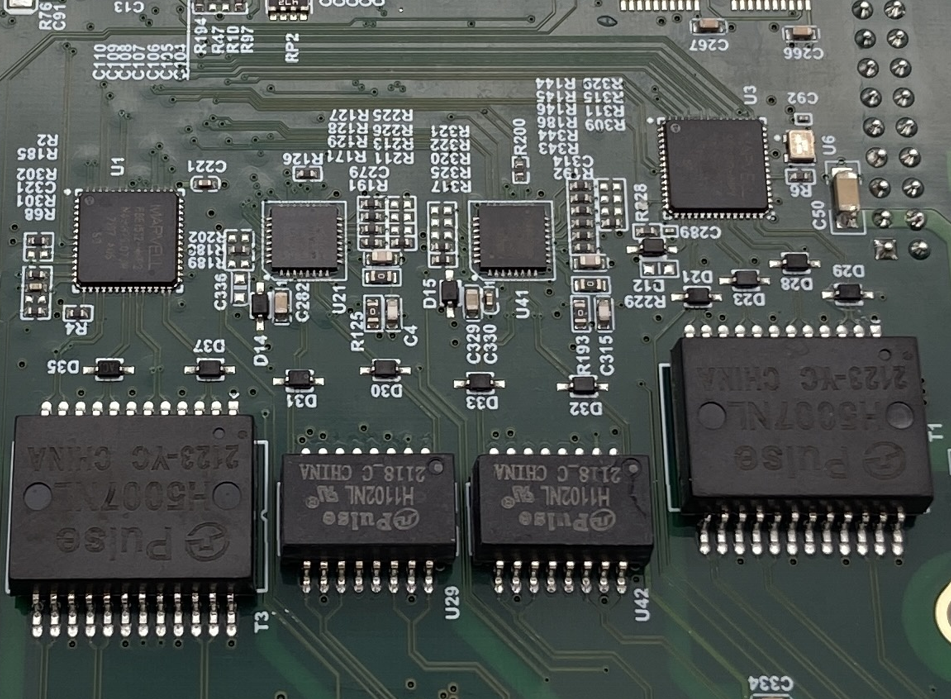

Components type:85

PCB size: 172*153mm

Minimum package size of resistance capacitance sensing: 0402

Minimum device pin spacing:0.5

Welding mode:Reflow soldering for double side+ Wave soldering.

Manufacturing process: SMD processing + cleaning + anti-static packaging

After the trial production, this products placed the first mass production order 1300pcs. and now shenzhen 1942 Technology was recognized as a reliable supllier for this PCB board.

The total number of front and back surface mount components is 246

The amount types are 70

The outer diameter of PCB is 095mm*095mm

The minimum package size of surface mounted components is 0402

The minimum pin spacing of surface mount components is 0.65mm

Components are soldered by double-sided reflow soldering machine

Though hole components soldered by wave soldering machine

More information about PCB

PCB NC drilling and milling machine is a typical point position motion control system, and is the key equipment for precision through hole machining of PCB. With the development of electronic products towards miniaturization and miniaturization, printed circuit boards have higher and higher requirements on the hole diameter, line width and line spacing of through holes. Accordingly, PCB numerical control system is developing towards the open direction of high speed, high precision, high reliability, system integration, flexibility and high intelligence.

MPC08 economical four axis motion controller is widely used in PCB numerical control drilling machine.

First of all, the movement mode of PCB numerical control drilling machine is mainly point to point movement, and its key technical index requirements are high speed and high precision. MPC08 is mainly used for point position motion control, which can quickly and accurately locate and drill down in an instant, and then when it is lifted, it can quickly move to the lower position hole while lifting when leaving the PCB board, thus greatly improving the working efficiency of the PCB numerical control drilling machine. The maximum output frequency of MPC08 is 4MHZ, meeting the high speed requirements of PCB drilling machine.

Secondly, PCB drilling machines need a large number of IO channels to monitor various equipment states and control output signals, and each MPC08 motion control card can control 16 general inputs and 16 general outputs, while there are 17 special input channels, which can be changed to general input channels when not needed, fully meeting the needs of PCB drilling machines for I/O channels.

In addition, MPC08 also provides users with a secondary development interface to meet their special function development needs.

More PCB &PCBA inforamtion pls visit technical articles