Shenzhen 1942 Technology Co., LTD is a one- stop service PCB manufacturer ,focus on PCBA used in Medical equipment, industrial control,IOT ,etc. We have 7 SMT line, we would like to share some key points about SMT and PCB and PCBA , hope it will be helpful.

Last artical ,we shared 2 points with all guys , now we will talk other key points to you .

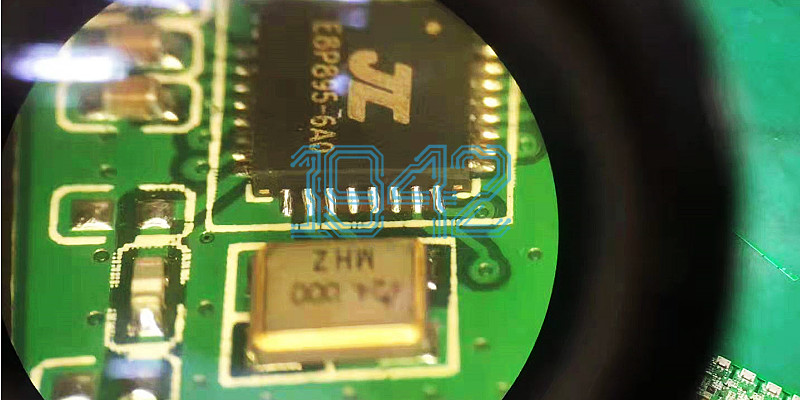

3. Water-based cleaning agent is a kind of cleaning agent that can be compatible with water and can be used with ultrasonic cleaning process. We call it Entire Water-based Environmentally ultrasonic cleaning process. Some highly concentrated water-based cleaning agents can be diluted with water at 1:10 or even 1:30, which is relatively cheap. Based on the principle of ultrasonic high-frequency vibration, the use of water-based cleaning agent can improve the cleaning effect, but usually it is difficult to clean it once or twice, it needs to be cleaned repeatedly, and it is easy to leave water spots after cleaning, so it needs to be dried in an oven after cleaning. However, some PCBs cannot use the water-based ultrasonic cleaning process. For example, the crystal oscillator is installed on the PCBs, or the product is cleaned when it is charged. At this time, if the water-based environmental friendly ultrasonic cleaning process is also used, it is likely to cause damage to the internal circuit of PCBs, thereby shortening the service life of the product.

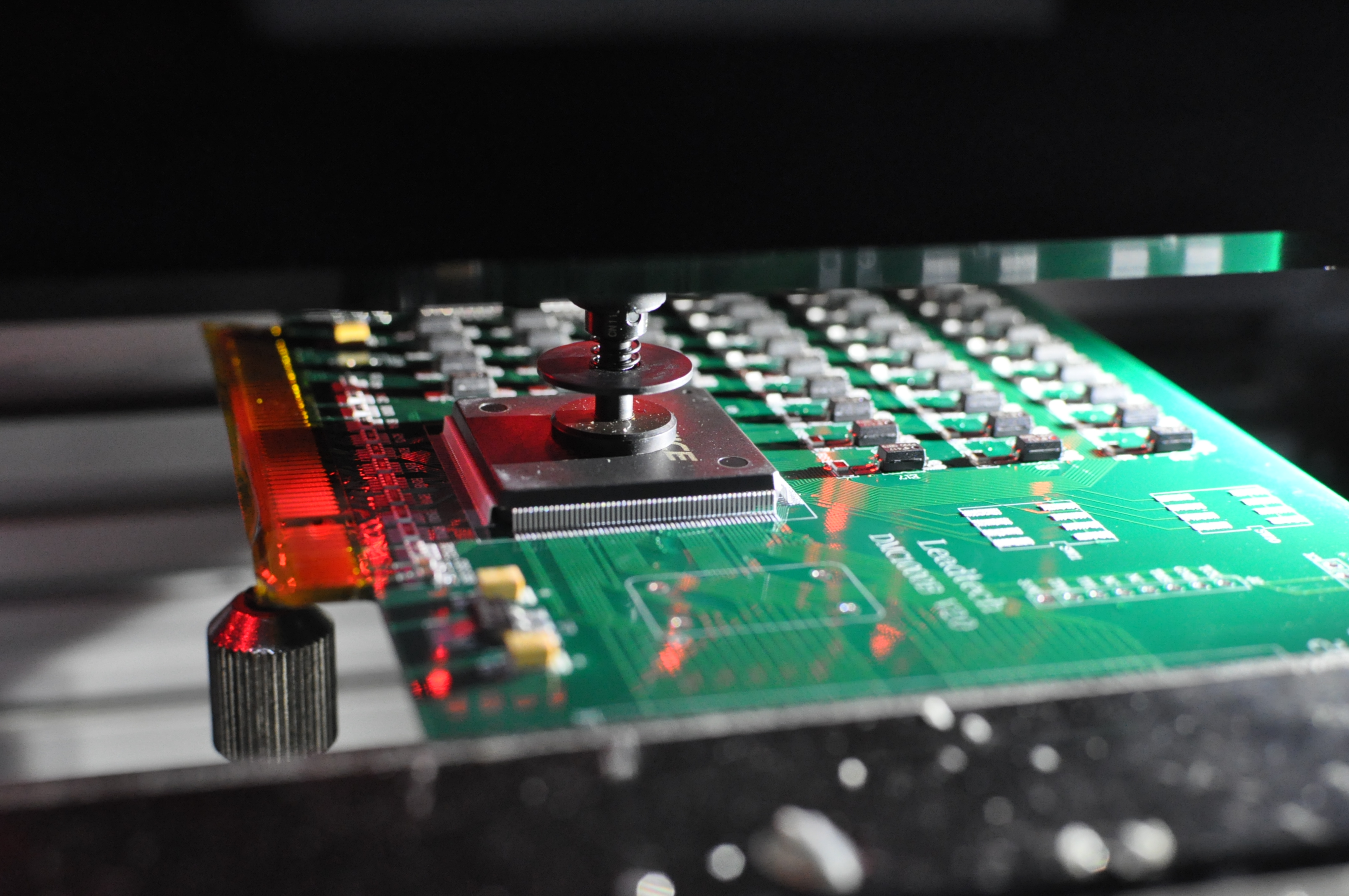

4. The surface dirt of PCBs most directly affects the appearance of PCBA. If placed or used in high temperature and humidity environment, the residue may absorb moisture and turn white. Due to the extensive use of leadless chips, micro BGA, chip level packaging (CSP) and 01005 in components, the distance between components and circuit boards is reduced, the size is miniaturized, and the assembly density is also increasing. If the halide is hidden under the components and cannot be cleaned, local cleaning may cause disastrous consequences due to the release of halide. PCB board cleaning is a process of dissolving and removing welding residues. The purpose of cleaning is to prolong the service life of products by ensuring good surface resistance and preventing electric leakage.

What any other suggestion do you have ?

#shenzhen 1942#PCBA manufacturer #PCBs# PCBassembly #SMT China #Internet of thing PCBA

2024-06-03

2024-06-03