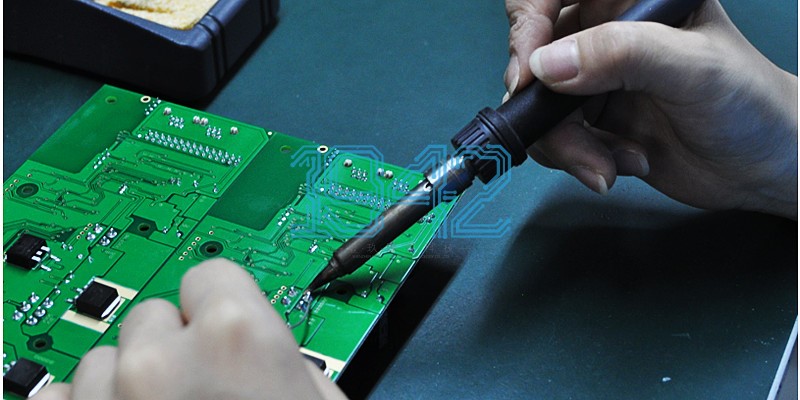

It will be applied a lot of technologies when we mounting components on PCB, so there are many requirements about the PCB. The difficulties of soldering will be increased if there is any defects of PCB. In order to give full play to the processing capacity of the equipment,improve the quality and the efficiency of the PCBA production, the designer should design reasonable PCB. Shenzhen 1942 Technology Co., LTD has sorted out some soldering process requirements for PCB boards when assemble, now we share those information with you.

1. Heat Resistance

With the development of PCBA processing technology and the improvement of environmental protection requirements, lead-free technology is widely used. However, the lead free technics required higher heat resistance of the PCB. When we use lead-free technology to go reflow soldering process, the temperature will reach up to 217 ~ 245 ° C, and will keep in this situation about 30 to 60 seconds, so good heat resistance of the PCB is very important.

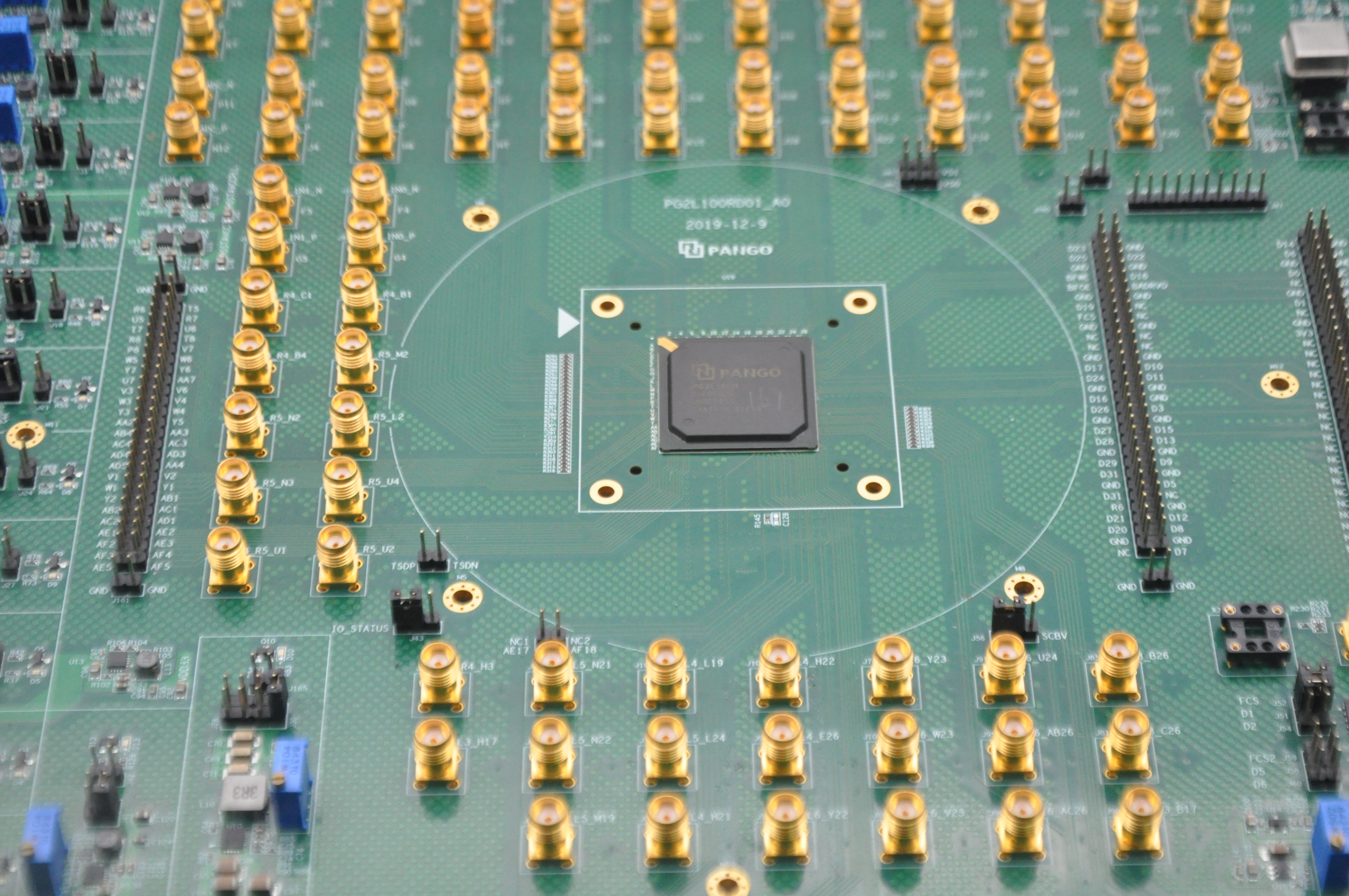

2. PCB shape

The shape of the PCB is generally rectangular, the optimal length-to-width ratio is 3:2 or 4:3, When the difference between length and width is too large, PCB is easy to warp and deform. Therefore , it is suggested to standardize the size of the PCB as much as possible, which can simplify the assembly process and reduce the cost.

3.PCB Size

Different SMT equipment on the PCB size requirements are not the same, in the early stage of PCB design, must consider the maximum and minimum PCB mounting size of the processing equipment, the general size of 50× 50mm ~ 400 × 460mm.

#shenzhen 1942 #PCBA factory #PCB assembly #SMT #DIP # China supplier #PCB size # PCBA sample #industrial control

2024-06-03

2024-06-03