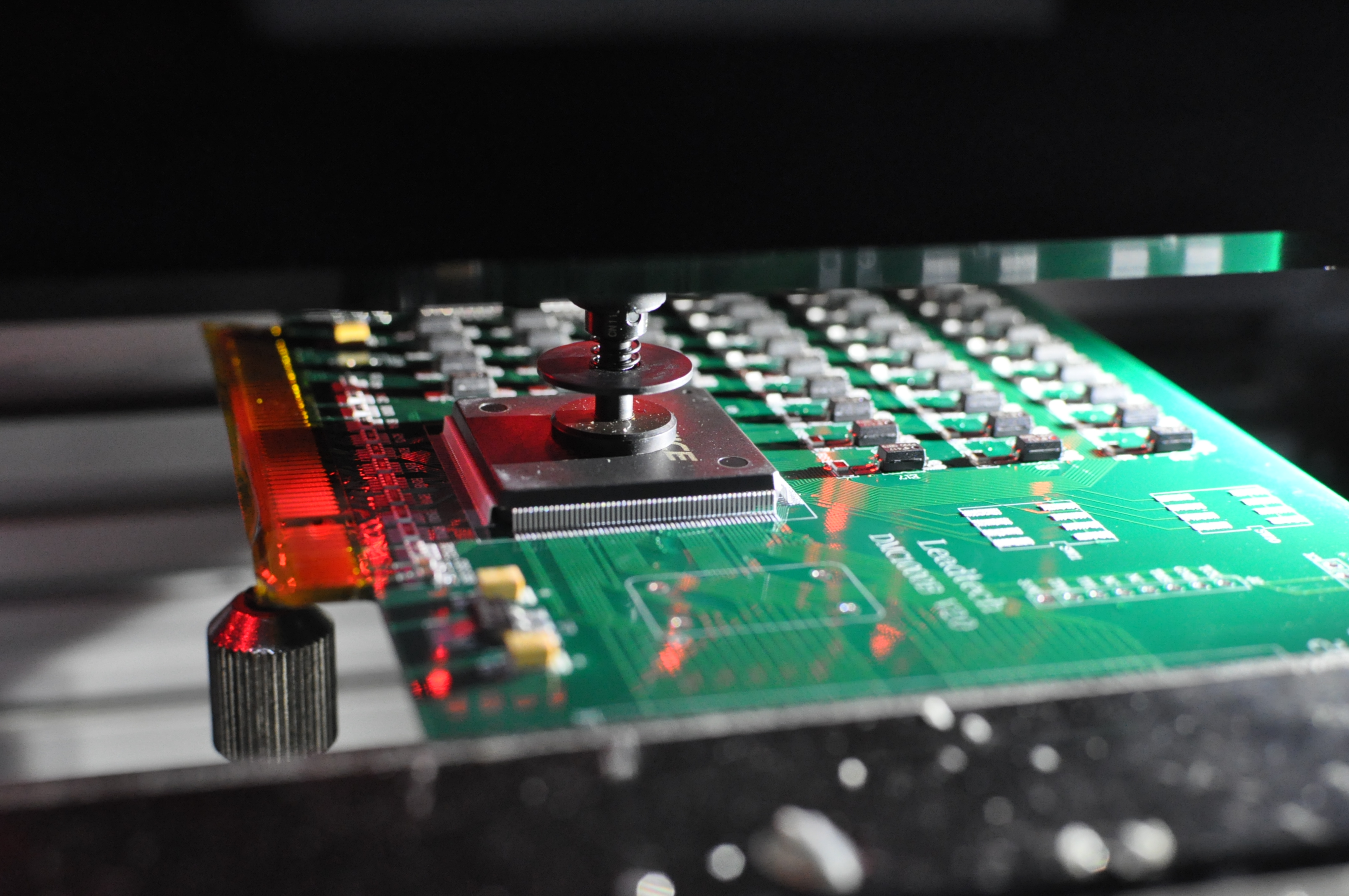

PCBA first article inspection means to inspect the first piece produced in each processing. First article inspection is an important quality control point to inspect the quality of PCBA. Mass production will be produced only after the first article meets the requirements .

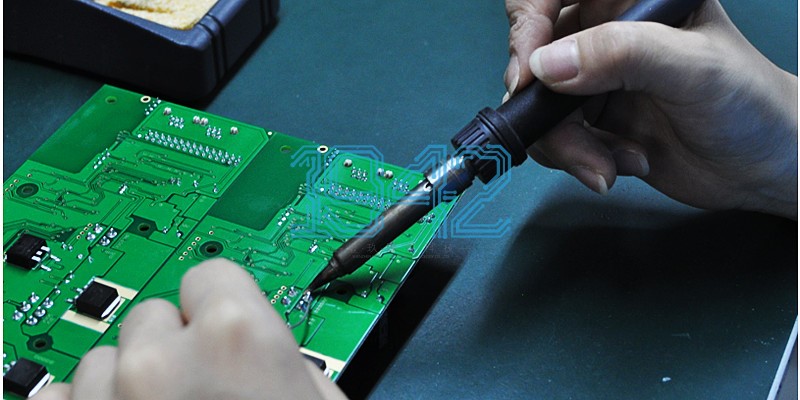

First article inspection is an effective measure to find problems as early as possible and prevent batch errors in Printed Circuit Board Assembly process. Through the first article inspection, we can find the errors of Printed circuit board, such as false sordering, lack of soldering, polar errrors, wrong materials and so on, so as to take corrective or improvement measures to prevent the occurrence of batch non-conforming products. It is a means to control the products quality in advance, and also an essential process to ensure the products quality and improve the production efficiency in PCBA process

First article inspection generally occurs in the first order of new products, shift change, line change, equipment parameter adjustment, and different practices of PCBA of the same model. When quality problems are found in the first article, they shall be timely reported and handled, and the unqualified items shall be re confirmed.

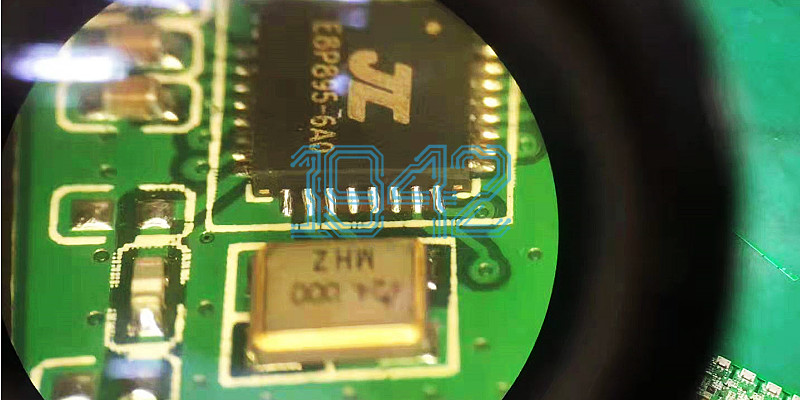

At present, many PCBA processing factories use the first article detector to test the first article. Just input the BOM, coordinates and reference diagram of the product, and then the system will automatically inspect the first article and check whether the data in the BOM is consistent with the sample. This can reduce the error of manual inspection, save labor costs, improve efficiency, and provide customers with high-quality products.

#Shenzhen 1942 Technology Co., LTD

#Professional SMT facotry

2024-06-03

2024-06-03